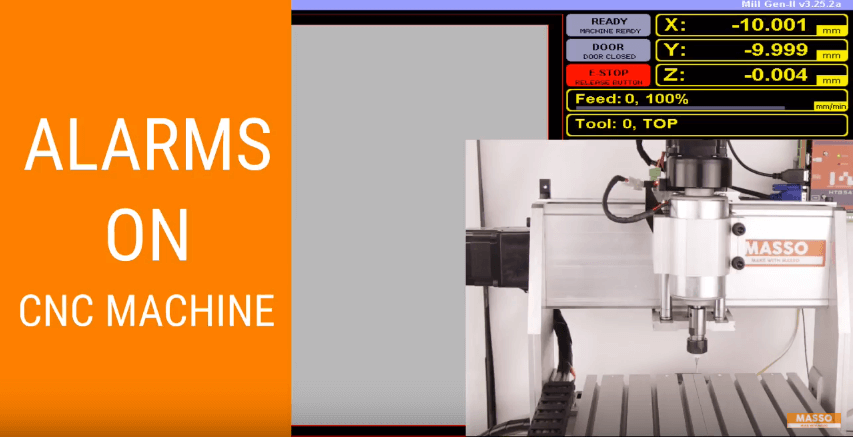

The Different Types of Alarms on CNC Machine

MASSO supports a series of alarms that are displayed on the screen to alert you for system related issues. These system alarms are an integrated part of the controller, they help you diagnose problems and at the same time help your machine safely.

Let’s see all the different alarms, what triggers them, and how to clear them in these easy to follow steps.

E-stop Alarm. When the MASSO boots up, the E-Stop Alarm flashes on the screen. For safety reasons, we need to confirm that the E-stop button is working and MASSO requests you to press the E-Stop and test the button.

How to clear this alarm?

- Simply press the E-stop button if already not pressed, next MASSO will ask you to release the button to clear the E-stop alarm.

- E-stop alarm is also displayed on the screen when the E-stop button is pressed.

Homing Alarm. This alarm basically tells you that the controller does not know the position of the axis and it needs to home the axis. To clear this alarm, you need to home the machine.

How to clear this alarm?

- Press ctrl + alt + home. Once homing is completed, the alarm will be cleared.

Door Open Alarm. This alarm is displayed on the screen when the machine door is in the open position. While the door is open, no G-codes can be run on the machine and manual JOG can be done.

How to clear this alarm?

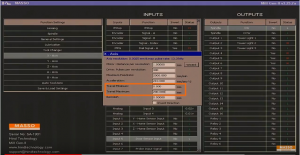

- If already not setup then go to the F1 screen then into the inputs list. Move down to any of the free inputs, select the door sensor input.

- Next, wire up the door sensor signal on this input.

- Opening and closing the door will activate or deactivate this alarm.

Soft Limit Alarm. Once enabled and properly configured, this alarm will prevent over travel to all axis on the machine. For soft limits to work properly, make sure they’re properly set up.

How to setup and use this alarm?

- Go to the F1 screen then to the general settings. Make sure the disable soft limits option is not checked. If this option is disabled, the soft limits won’t work.

- Make sure that when you do the calibration for each axis, the minimum and the maximum travel of each axis is defined as per your machine travel because this is the value that is used internally for soft limits.

- To clear this alarm you need to give a valid G-code command and that can be any motion command or any G or M codes.

Hard Limit Alarms. From version 3.25 these alarms are triggered by the homing sensors or switches if during motion the system over travels due to mechanical or electrical issues. The system will display an alarm on the screen, telling you which axis caused the alarm, at the same time will stop the spindle and put the system in feed hold.

How to clear this alarm?

- To clear this alarm, first check what caused this alarm, either the settings on the system or something mechanically might be wrong.

- Once the issue has been fixed, you simply press ctrl + alt + home to home the machine and clear the alarm.

Probe Alarm. While probing, you can get alarms in two conditions:

- When you do a probing cycle and you ask the axis to move a certain distance and the probe is not triggered within this motion

- If your probe is already touching the work piece

How to clear this alarm?

- To clear this alarm, we just need a valid G-Code command, generally a G0 or G1 motion command will clear this alarm.

Tool Error Alarm. This is displayed when you try to load a tool that is not supported by MASSO. MASSO supports 32 tools from tool number 0 to tool number 31. If the requested tool number is beyond this limit, an alarm will be displayed.

How to clear this alarm?

- To clear tool alarms, give any valid G-code command

Motor Drive Alarm. This alarm is triggered by the stepper or servo motor drives when they go into any fault condition. The fault can be caused either by any electrical issue or the motor might be stuck. As soon as MASSO receives this signal, it will put the system into feed hold and will stop the spindle.

How to set up and clear this alarm?

- Go to the F1 screen and use any of the free inputs. Assign Motor Alarm Input from the list. There are alarm inputs for each axis motors so you can connect all axis motors to different inputs. If any of those motors give any alarm, the system will go into feed hold and display a message on the screen.

- To clear this alarm, we first need to find the issue that caused the alarm. Again it can be an electrical or mechanical issue. Once it’s fixed, press ctrl + alt + home to home the machine.

Lubricant Low Alarm. On machines where you have lubrication system to lubricate your slides, the system often has switches or sensors to trigger when the lubricant goes low. Those switches or sensors output can be connected to the MASSO.

How to setup this alarm?

- Go to the F1 screen and use any of the free inputs and assign it as Lubricant Low Alarm input. Now wire the lubricant level sensor to this input.

- This alarm will display a message on the screen and it won’t stop any motion. However, it will still display an alarm to alert you that the oil level has gone low.

- Once the lubrication tank has been refilled and the signal goes away, this alarm will automatically clear.

For demonstrations and more tips, please watch the full video here:

Post a comment

You must be logged in to post a comment.