IMPORTANT! – Please read the below release notes first.

IMPORTANT! – Take screenshots of your current controller settings including all setup and calibration data including input and output function assignments and invert status as after loading this software your controller might reset to default settings or controller settings might change.

Also save the controller settings to settings file and text files. The settings file will be required to load settings if later you want to install the older software version.

IMPORTANT: After loading this software version, all tools data in the F4 screen will be erased and the user must manually add all tools data in F4 screen before using the machine.

IMPORTANT: This version has new tool changer logic which requires all the inputs and outputs to be reassigned and calibration data entered into the tool changer settings in the F1 screen before using the machine.

IMPORTANT: From this version tool changer logic will change to tool number 1 to tool number 100. In earlier versions tool changers used to work from tool 0 to tool 99. These changes have been done to add support for Multi-Head systems.

NEW

- QR Scanner support added – MASSO G3 controllers now supports option to load gcode files by scanning QR codes from a USB QR scanner. For more information CLICK HERE

- Multi-Head support – The all new Multi-Head logic allows the user to control advanced multiple heads on a machine. Multiple spindles, Dry run laser, engraving laser, plasma, oxy, waterjet, spribe tool, pen and camera control can be done for complex machining jobs. For more information CLICK HERE

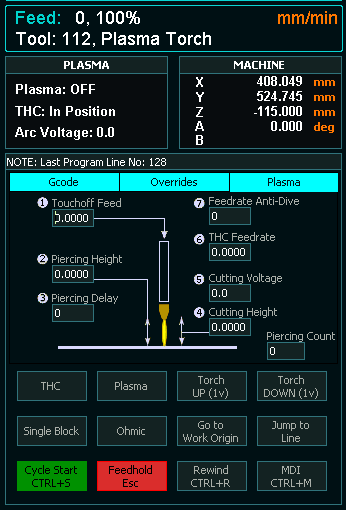

- Advanced plasma control – This version introduces a totally new way of programing and running plasma cutting head. All plasma cutting parameters can be either programmed and edited on the screen or can be set using the new G200 gcode. This logic supports the new MASSO DTHC module that can be connected to the MASSO G3 unit to read palsma voltages, this feature allows the user to set the required cutting voltage in each gcode file and the user does not need to program cutting voltages manually in an external THC module. For more information CLICK HERE

- Engraving laser support – Engraving laser support allows easy setup and gcode control of lasers with dedicated PWM output for laser control. For more information CLICK HERE

- Spindle motor STEP & DIRECTION control – With this version the user has option to control spindle servo motors with STEP & DIRECTION control. NOTE: spindle acceleration and deacceleration needs to be managed by the drive.

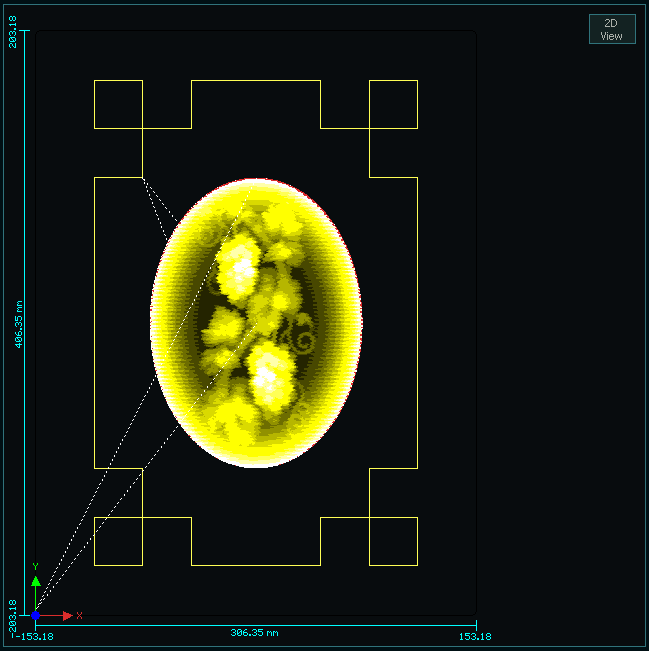

- Depth map – 3D engraving files or laser engraving files can now be displayed with the depth map option which makes it easier to visulize the process.

IMPROVEMENTS & BUG FIXES

- Added logic to hide MSG box by passing no text in MSG command. For more information CLICK HERE

- Improvements to Jump To Line logic.

- Automatic sorting of files and folders when a USB flash drive is connected to MASSO.

- Added go to Line button logic to gcode editor.

- Improvements to drilling cycles logic and now Jump To Line can be used with drilling cycles.