IMPORTANT! – Please read the below release notes first.

IMPORTANT! – Take screenshots of your current controller settings including all setup and calibration data including input and output function assignments and invert status as after loading this software your controller might reset to default settings or controller settings might change.

Also save the controller settings to settings file and text files. The settings file will be required to load settings if later you want to install the older software version.

IMPORTANT: After loading this software version, all tools data in the F4 screen will be erased and the user must manually add all tools data in F4 screen before using the machine.

IMPORTANT: This version has new tool changer logic which requires all the inputs and outputs to be reassigned and calibration data entered into the tool changer settings in the F1 screen before using the machine.

IMPORTANT: From this version tool changer logic will change to tool number 1 to tool number 100. In earlier versions tool changers used to work from tool 0 to tool 99. These changes have been done to add support for Multi-Head systems.

NEW

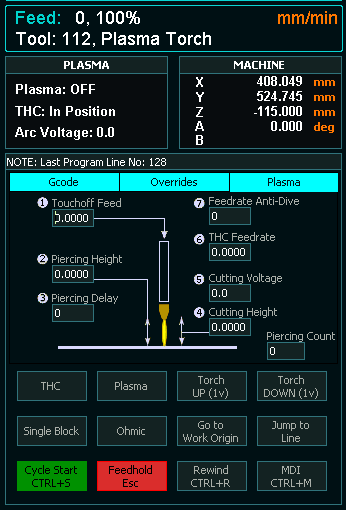

- Advanced plasma control – Addition of S command to new plasma G200 gcode to support for thick material cutting. For more information CLICK HERE

- Support has been added for old plasma gcode files not using the new G200 gcode format. The user can use their existing gcode files by deactivating G200 at starting of the gcode file. To do this either add G200 with no parameters at the start of the file or via MDI by typing the command G200. For more information CLICK HERE

- Support added for external Plasma THC with UP/DOWN signals.

- Support added for external Plasma Arc OK signal. Can be used with external THC or MASSO DTHC module if plasma source provides external Arc OK signal.

IMPROVEMENTS & BUG FIXES

- More details added to printable settings file for easy debugging.

- Spindle air clean option added for mill tool changers.

- Bug fixes to Multi-Head logic that was causing tool changer homing issues.

- Lathe threading bug fix where the first threading cycle used to take upto 20 seconds to start cutting.