IMPORTANT! – Please read the below release notes first.

IMPORTANT! – Take screenshots of your current controller settings including all setup and calibration data including input and output function assignments and invert status as after loading this software your controller might reset to default settings or controller settings might change.

IMPORTANT: After loading this software version, all tools data in the F4 screen will be erased and the user must manually add all tools data in F4 screen before using the machine.

IMPORTANT: This version has new tool changer logic for mill linear tool changer which requires all the inputs and outputs to be reassigned and calibration data entered into the tool chnager settings in the F1 screen before using the machine.

IMPORTANT: From v4.0, Caps lock off during power up: As per user feedback the caps lock status on power up will be set to off state, please check caps status when entering your password.

NEW

- Multi-Head – Fully integrated software now supports up to 5 spindles, lasers, plasma, oxy, waterjet, scribe tool and more options. Different types of heads can be mounted and used on the machine with automatic head offsets. For more information CLICK HERE

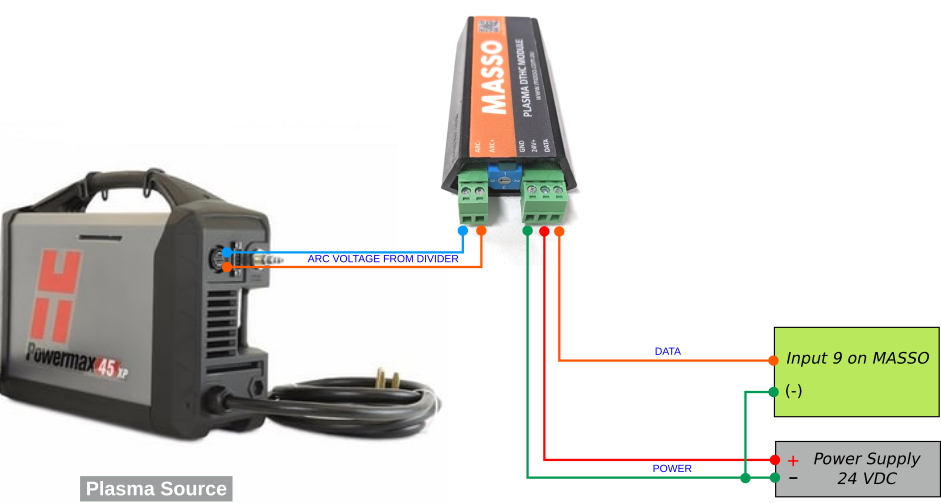

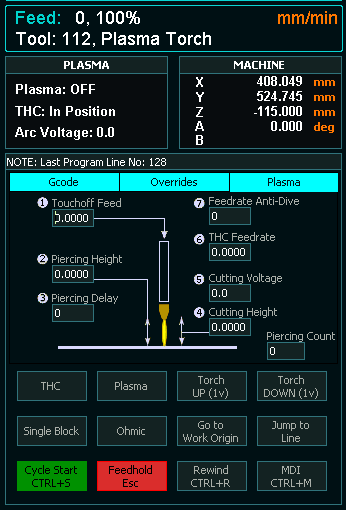

- MASSO DTHC module for plasma machine torch height control. For more information CLICK HERE

- Advanced plasma control – Addition of S command to new plasma G200 gcode to support for thick material cutting. For more information CLICK HERE

- Support has been added for old plasma gcode files not using the new G200 gcode format. The user can use their existing gcode files by deactivating G200 at starting of the gcode file. To do this either add G200 with no parameters at the start of the file or via MDI by typing the command G200. For more information CLICK HERE

- Support added for external Plasma THC with UP/DOWN signals.

- Support added for external Plasma Arc OK signal. Can be used with external THC or MASSO DTHC module if plasma source provides external Arc OK signal.

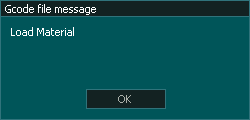

- New command support “MSG” to give messages to user when running a job. For more information CLICK HERE

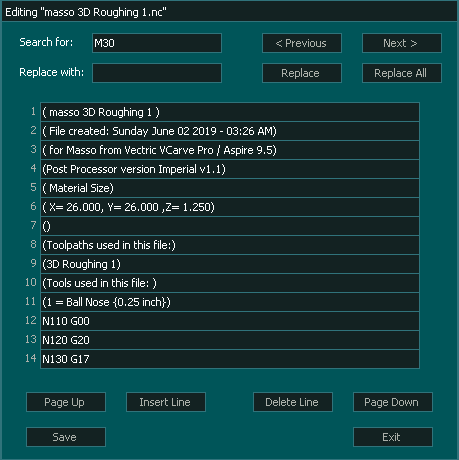

- New Gcode file edtor – Edit any size of gcode files with options to search and replace text. For more information CLICK HERE

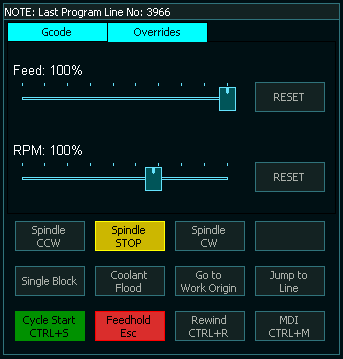

- New slider bars to control feed and spindle RPM overrides while machining.

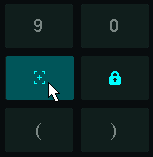

- For vertical touch screen interface, added buttons to take screenshots and lock controller.

- Added on screen indicators to show current mode status of the machine.

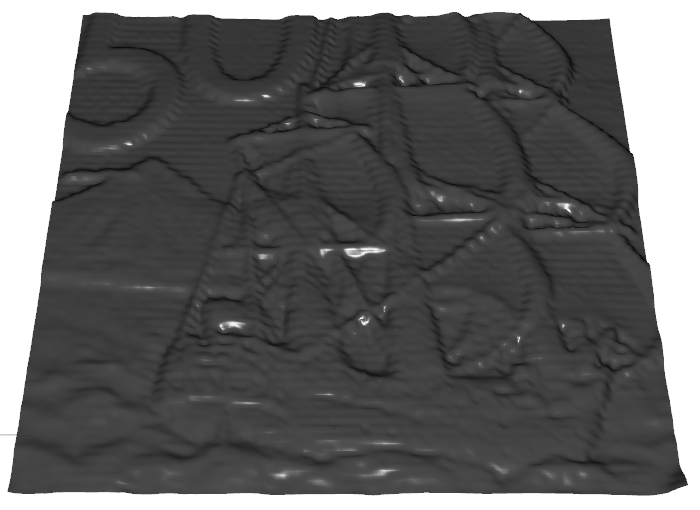

- Added G38.6 Digitizing Probing Cycle for saving probed points to file for maping surfaces and auto leveling. For more information CLICK HERE

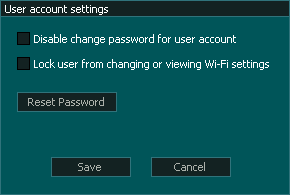

- Added options to user account settings for admin to restrict user from changing Wi-Fi settings and to reset user password.

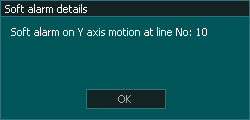

- New message logic to display gcode line infromation for soft limit alarms.

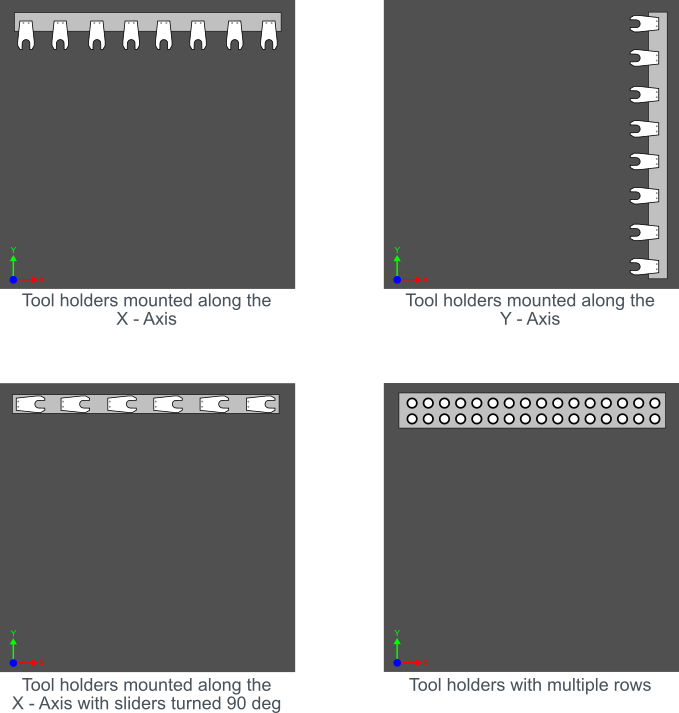

- New logic for Mill version to support linear tools with different layouts and multiple rows:

- Both Linear Tool Changer Type 1 & Type 2 now support this new logic.

- The user can have different types of tool holder options.

- For more information CLICK HERE

IMPROVEMENTS & BUG FIXES

- Wi-Fi not responding issue fix: Bug fix that was causing MASSO to stop communicating with MASSO Link.

- Fixed issues with gcode file transfer from MASSO Link where the gcode file transfer to USB root folder was causing issues.

- Probing window cursor in data boxes is now automatically set to start of text which makes is easy to view and enter data.

- Lathe 4 Bit Digital Signal Output Turret logic improvements to resolve input signal invert issue.

- Improvements to Plasma Jump To Line logic to auto resume last cut.

- Improvements to motor alarm logic to show which motor caused Alarm during machine homing.

- Improvements to backlash logic.

- Improvements to probing logic.

- Improvements to Lathe threading cycles logic.